|

Interface |

Benefits |

|

DRIVE-CLiQ |

- Very high data transfer rates possible - Advantages in time-critical applications - Simple and quick automatic configuration using electronic rating plates - Fast and easy diagnostics with a single tool - One interface for connecting drives as well as indirect and direct measurement systems to the CNC. |

|

SSI |

- Advantages in time-critical applications |

|

EnDat 2.1 |

- High data transfer rate, bidirectional - Advantages in time-critical applications - Incremental track with 1 Vpp - Connection via SINAMICS Sensor Modules SMC/SME |

|

PROFIBUS DP-V2 |

- Parameterizable built-on encoder - Reduced wiring overhead in plants with a large number of encoders - Isochronous operation and direct data exchange |

|

PROFINET IO |

- Parameterizable built-on encoder - Reduced wiring overhead in plants with a large number of encoders - Supports conformity class C (IRT communication), B, A (RT communication) - IRT (isochronous mode) - 2 ports - Media redundancy with MRPD, MRP |

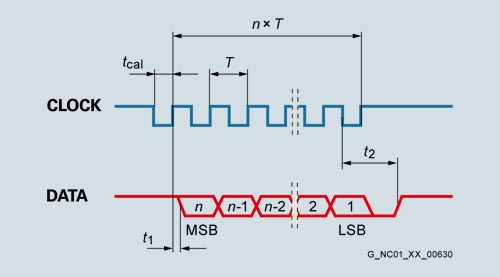

Data transfer for absolute encoders with SSI interface

n = data word length (13 bits for single-turn and 25 bits for multi-turn)

T = 1 ... 10 µs

t cal = ≤ 5 µs

t 1 = ≤ 0.4 µs (without cable)

t 2 = 17 ... 20 µs

|

Article No. |

|

6FX2001-5.D..-1AA0 |

6FX2001-5.S.. |

6FX2001-5.E.. |

|

Product name |

|

Motion Control encoder |

Motion Control encoder |

Motion Control encoder |

|

Product designation |

|

Absolute encoder |

Absolute encoder |

Absolute encoder |

|

Operating voltage DC |

V |

24 |

4.75 ... 30 |

3.6 ... 14 |

|

Current consumption, approx. |

|

|

|

|

| Single-turn |

mA |

37 |

90 |

90 |

| Multi-turn |

mA |

43 |

120 |

120 |

|

Interface |

|

DRIVE-CLiQ |

SSI |

EnDat 2.1 |

|

Clock input |

|

– |

Differential cable receiver acc. to EIA standard RS485 |

Differential cable receiver acc. to EIA standard RS485 |

|

Data output |

|

DRIVE-CLiQ |

Differential cable driver acc. to EIA standard RS485 |

Differential cable driver acc. to EIA standard RS485 |

|

Short-circuit strength |

|

Yes |

Yes |

Yes |

|

Transfer rate |

Mbit/s |

100 |

– |

– |

|

Transfer rate |

kHz |

– |

100 ... 1000 |

100 ... 2000 |

|

Maximum speed |

|

|

|

|

| Electrical |

rpm |

14000 |

– |

– |

| At ± 1 bit accuracy |

rpm |

– |

5000 |

5000 |

| At ± 12 bit accuracy |

rpm |

12000 |

– |

– |

| At ± 100 bit accuracy |

rpm |

– |

12000 |

12000 |

| Mechanical |

|

|

|

|

| Single-turn |

rpm |

15000 |

15000 |

15000 |

| Multi-turn |

rpm |

12000 |

12000 |

12000 |

|

Cable length to downstream electronics, maximum1) |

m (ft) |

100 (328) |

– |

– |

| Up to 300 kHz cycle |

m (ft) |

– |

100 (328) |

150 (492) |

| Up to 1 MHz cycle |

m (ft) |

– |

50 (164) |

50 (164) |

| Up to 2 MHz cycle |

m (ft) |

– |

– |

10 (32.8) |

|

Connection |

|

Radial flange outlet M12 |

Axial/radial flange outlet M23 |

Axial/radial flange outlet M23 |

|

Resolution |

|

|

|

|

| Single-turn |

bit |

24 |

13 |

13 |

| Multi-turn |

bit |

36 |

25 |

25 |

|

Frame |

|

|

|

|

| Single-turn |

bit |

– |

13 |

According to EnDat specification |

| Multi-turn |

bit |

– |

25 |

According to EnDat specification |

|

Incremental track |

S/R |

2048, 1 Vpp |

– |

512, 1 Vpp |

|

Code type |

|

|

|

|

| Transfer |

|

DRIVE-CLiQ |

Gray, fir tree format |

Dual |

|

Parameterization capability |

|

|

|

|

| Preset |

|

– |

Set to zero |

– |

| Counting direction |

|

– |

Yes |

– |

|

Accuracy |

arcsec |

± 20 |

± 60 |

± 60 |

|

Starting torque at 20 °C (68 °F) |

Nm (lbf‑ft) |

≤ 0.01 (0.01) |

≤ 0.01 (0.01) |

≤ 0.01 (0.01) |

|

Solid shaft loading capacity |

|

|

|

|

| n ≤ 6000 rpm |

|

|

|

|

| Axial |

N (lbf) |

40 (8.99) |

40 (8.99) |

40 (8.99) |

| Radial at shaft extension |

N (lbf) |

60 (13.5) |

60 (13.5) |

60 (13.5) |

| n > 6000 rpm |

|

|

|

|

| Axial |

N (lbf) |

10 (2.25) |

10 (2.25) |

10 (2.25) |

| Radial at shaft extension |

N (lbf) |

20 (4.50) |

20 (4.50) |

20 (4.50) |

|

Shaft diameter |

|

|

|

|

| Synchro flange Solid shaft |

mm (in) |

6 (0.24) |

6 (0.24) |

6 (0.24) |

| Clamp flange Solid shaft |

mm (in) |

10 (0.39) |

10 (0.39) |

10 (0.39) |

| Torque arm Hollow shaft |

mm (in) |

10 (0.39) or 12 (0.47) |

– |

– |

|

Shaft length |

|

|

|

|

| Synchro flange |

mm (in) |

10 (0.39) |

10 (0.39) |

10 (0.39) |

| Clamp flange |

mm (in) |

20 (0.79) |

20 (0.79) |

20 (0.79) |

|

Angular acceleration, maximum |

rad/s2 |

105 |

105 |

105 |

|

Moment of inertia of rotor |

|

|

|

|

| Solid shaft |

kgm2 (lbf-in-s2) |

≤ 2.9 × 10-6 (2.57 × 10-5) |

≤ 2.9 × 10-6 (2.57 × 10-5) |

≤ 2.9 × 10-6 (2.57 × 10-5) |

| Hollow shaft |

kgm2 (lbf-in-s2) |

4.6 × 10-6 (4.07 × 10-5) |

– |

– |

|

Vibration (55 ... 2000 Hz) according to EN 60068‑2‑6 |

|

|

|

|

| Solid shaft |

m/s2 (ft/s2) |

≤ 300 (984) |

≤ 300 (984) |

≤ 300 (984) |

| Hollow shaft |

m/s2 (ft/s2) |

≤ 150 (492) |

– |

– |

|

Shock according to EN 60068‑2‑27 |

|

|

|

|

| 6 ms |

|

|

|

|

| Solid shaft |

m/s2 (ft/s2) |

≤ 2000 (6562) |

≤ 2000 (6562) |

≤ 2000 (6562) |

| Hollow shaft |

m/s2 (ft/s2) |

≤ 1000 (3281) |

– |

– |

|

Degree of protection |

|

|

|

|

| At housing |

|

IP67 |

IP67 |

IP67 |

| At shaft input |

|

IP64 |

IP64 |

IP64 |

|

Ambient temperature, during |

|

|

|

|

| Operation |

°C (°F) |

-30 ... +100 (-22 ... +212) |

-40 ... +100 (-40 ... +212) |

-40 ... +100 (-40 ... +212) |

|

Net weight |

|

|

|

|

| Single-turn |

kg (lb) |

0.35 (0.77) |

0.35 (0.77) |

0.35 (0.77) |

| Multi-turn |

kg (lb) |

0.35 (0.77) |

0.35 (0.77) |

0.35 (0.77) |

|

EMC |

|

EMC Directive 2014/30/EC and regulations of EMC directives (applicable basic standards) |

EMC Directive 2014/30/EC and regulations of EMC directives (applicable basic standards) |

EMC Directive 2014/30/EC and regulations of EMC directives (applicable basic standards) |

|

Certificate of suitability |

|

CE, CSA, UL |

CE, CSA, UL |

CE, CSA, UL |

S/R = signals/revolution

|

Article No. |

|

6FX2001-5.P.. |

6FX2001-5.N.. |

|

Product name |

|

Motion Control encoder |

Motion Control encoder |

|

Product designation |

|

Absolute encoder with PROFIBUS DP |

Absolute encoder with PROFINET IO |

|

Operating voltage DC |

V |

10 ... 30 |

10 ... 30 |

|

Current consumption, approx. |

|

|

|

| Single-turn |

mA |

300 ... 100 (2.5 W) |

400 ... 130 (4 W) |

| Multi-turn |

mA |

300 ... 100 (2.5 W) |

400 ... 130 (4 W) |

|

Interface |

|

PROFIBUS DP-V2 |

PROFINET IO with RT/IRT |

|

Clock input |

|

Differential cable receiver acc. to EIA standard RS485 |

2 ports IRT |

|

Data output |

|

Differential cable driver acc. to EIA standard RS485 |

2 ports IRT |

|

Short-circuit strength |

|

Yes |

Yes |

|

Transfer rate |

Mbit/s |

12 |

100 |

|

LED for diagnostics |

|

Green/red |

Green/red/yellow/orange |

|

Maximum speed |

|

|

|

| Electrical |

|

|

|

| At ± 1 bit accuracy |

rpm |

5000 |

5000 |

| Mechanical |

|

|

|

| Single-turn |

rpm |

12000 |

12000 |

| Multi-turn |

rpm |

6000 |

6000 |

|

Cable length to downstream electronics, maximum1) |

|

|

|

| Up to 93.75 kbit/s |

m (ft) |

1200 (3937) |

– |

| Up to 1.5 Mbit/s |

m (ft) |

200 (656) |

– |

| Up to 12 Mbit/s |

m (ft) |

100 (328) |

100 (328) |

|

Number of nodes |

|

99 |

– |

|

Connection |

|

Terminal block with address selector switch and bus terminating resistor in removable cover with radial cable glands (3 units) |

2 × M12 connector, 4-pole for PROFINET ports |

| Cable diameter |

mm (in) |

6.5 ... 9 (0.26 ... 0.35) |

– |

|

Resolution |

|

|

|

| Single-turn |

bit |

13 |

13 with V 4.1, 16 with V 4.2 |

| Multi-turn |

bit |

27 |

27 with V 4.1, 30 with V 4.2 |

|

Frame |

|

According to PNO encoder profile V 4.1 |

According to PNO encoder profile V 4.1 and V 4.2 |

|

Code type |

|

|

|

| Sampling |

|

Gray |

Gray |

| Transfer |

|

Binary, PROFIBUS |

Binary, PROFINET |

|

Bus load, approx. |

|

|

|

| At 12 Mbit/s per encoder |

µs |

20 |

– |

|

Cycle time |

ms |

1 |

1 ... 100 |

|

Parameterization capability |

|

|

|

| Resolution per revolution |

|

1 ... 8192 |

1 ... 8192 |

| Total resolution |

|

1 ... 134217728 |

1 ... 134217728 |

| Preset |

|

Yes |

Yes |

| Counting direction |

|

Yes |

Yes |

| Velocity signal |

|

Yes |

Yes |

| Limit switches |

|

Yes, 2 units |

No |

| Isochronous mode |

|

Yes |

Yes |

| Direct data exchange |

|

Yes |

No |

|

Online parameterization |

|

Yes |

Yes |

|

PNO certificate |

|

Yes |

Yes |

|

Supported profiles |

|

PNO encoder profile V 4.1 |

PNO encoder profile V 4.1 and V 4.2 |

|

Accuracy with 8192 steps |

arcsec |

± 79 (± ½ LSB) |

± 79 (± ½ LSB) |

|

Friction torque at 20 °C (68 °F) |

Nm (lbf‑ft) |

≤ 0.03 (0.02) |

≤ 0.03 (0.02) |

|

Starting torque at 20 °C (68 °F) |

Nm (lbf‑ft) |

≤ 0.03 (0.02) |

≤ 0.03 (0.02) |

|

Shaft loading capacity |

|

|

|

| n ≤ 6000 rpm |

|

|

|

| Axial |

N (lbf) |

40 (8.99) |

40 (8.99) |

| Radial at shaft extension |

N (lbf) |

110 (24.7) |

110 (24.7) |

| n > 6000 rpm |

|

|

|

| Axial |

N (lbf) |

10 (2.25) |

10 (2.25) |

| Radial at shaft extension |

N (lbf) |

20 (4.50) |

20 (4.50) |

|

Shaft diameter |

|

|

|

| Synchro flange Solid shaft |

mm (in) |

6 (0.24) |

6 (0.24) |

| Clamp flange Solid shaft |

mm (in) |

10 (0.39) |

10 (0.39) |

| Torque arm Hollow shaft2) |

mm (in) |

5 ... 15 (0.20 ... 0.59) |

5 ... 15 (0.20 ... 0.59) |

|

Shaft length |

|

|

|

| Synchro flange |

mm (in) |

10 (0.39) |

10 (0.39) |

| Clamp flange |

mm (in) |

20 (0.79) |

20 (0.79) |

|

Angular acceleration, maximum |

rad/s2 |

105 |

105 |

|

Moment of inertia of rotor |

|

|

|

| Solid shaft |

kgm2 (lbf-in-s2) |

1.90 × 10-6 (1.68 × 10-5) |

1.90 × 10-6 (1.68 × 10-5) |

| Hollow shaft |

kgm2 (lbf-in-s2) |

2.80 × 10-6 (2.47 × 10-5) |

2.80 × 10-6 (2.47 × 10-5) |

|

Vibration (55 ... 2000 Hz) according to EN 60068‑2‑6 |

m/s2 (ft/s2) |

≤ 100 (328) |

≤ 100 (328) |

|

Shock according to EN 60068‑2‑27 |

|

|

|

| 2 ms |

m/s2 (ft/s2) |

≤ 2000 (6562) |

≤ 2000 (6562) |

| 6 ms |

m/s2 (ft/s2) |

≤ 1000 (3281) |

≤ 1000 (3281) |

|

Degree of protection |

|

|

|

| At housing |

|

IP67 |

IP67 |

| At shaft input |

|

IP64 |

IP64 |

|

Ambient temperature, during |

|

|

|

| Operation |

°C (°F) |

-40 ... +85 (-40 ... +185) |

-40 ... +85 (-40 ... +185) |

|

Net weight |

|

|

|

| Single-turn |

kg (lb) |

0.4 (0.88) |

0.4 (0.88) |

| Multi-turn |

kg (lb) |

0.5 (1.1) |

0.5 (1.1) |

|

EMC |

|

EMC Directive 2014/30/EC and regulations of EMC directives (applicable basic standards) |

EMC Directive 2014/30/EC and regulations of EMC directives (applicable basic standards) |

|

Certificate of suitability |

|

CE, CSA, UL |

CE, CSA, UL |

1) Observe the max. permissible cable length of the connected module.

2) Hollow shaft diameter of 12 mm, 10 mm or 8 mm (0.47 in, 0.39 in or 0.31 in) possible using supplied reduction sleeves.