.png)

.png)

.png)

.png)

| Number of positions | 1 |

| Number of levels | 1 |

| Number of connections | 2 |

| Nominal cross section | 2.5 mm² |

| Color | green-yellow |

| Insulating material | PA |

| Flammability rating according to UL 94 | V0 |

| Rated surge voltage | 8 kV |

| Degree of pollution | 3 |

| Overvoltage category | III |

| Insulating material group | I |

| Maximum power dissipation for nominal condition | 0.77 W |

| Open side panel | No |

| Terminal block mounting | 0.5 Nm ... 0.6 Nm (PE foot with mounting screw, M2.5) |

| Relative insulation material temperature index (Elec., UL 746 B) | 130 °C |

| Temperature index of insulation material (DIN EN 60216-1 (VDE 0304-21)) | 130 °C |

| Static insulating material application in cold | -60 °C |

| Behavior in fire for rail vehicles (DIN 5510-2) | Test passed |

| Flame test method (DIN EN 60695-11-10) | V0 |

| Oxygen index (DIN EN ISO 4589-2) | >32 % |

| NF F16-101, NF F10-102 Class I | 2 |

| NF F16-101, NF F10-102 Class F | 2 |

| Surface flammability NFPA 130 (ASTM E 162) | passed |

| Specific optical density of smoke NFPA 130 (ASTM E 662) | passed |

| Smoke gas toxicity NFPA 130 (SMP 800C) | passed |

| Calorimetric heat release NFPA 130 (ASTM E 1354) | 28 MJ/kg |

| Fire protection for rail vehicles (DIN EN 45545-2) R22 | HL 1 - HL 3 |

| Fire protection for rail vehicles (DIN EN 45545-2) R23 | HL 1 - HL 3 |

| Fire protection for rail vehicles (DIN EN 45545-2) R24 | HL 1 - HL 3 |

| Fire protection for rail vehicles (DIN EN 45545-2) R26 | HL 1 - HL 3 |

| Width | 5.2 mm |

| Length | 42.5 mm |

| Height NS 35/7,5 | 42 mm |

| Height NS 35/15 | 49.5 mm |

| Height NS 32 | 47 mm |

| Note | Please observe the current carrying capacity of the DIN rails. |

| Connection method | Screw connection |

| Connection in acc. with standard | IEC 60947-7-2 |

| Conductor cross section solid min. | 0.2 mm² |

| Conductor cross section solid max. | 4 mm² |

| Conductor cross section AWG min. | 24 |

| Conductor cross section AWG max. | 12 |

| Conductor cross section flexible min. | 0.2 mm² |

| Conductor cross section flexible max. | 2.5 mm² |

| Min. AWG conductor cross section, flexible | 24 |

| Max. AWG conductor cross section, flexible | 14 |

| Conductor cross section flexible, with ferrule without plastic sleeve min. | 0.25 mm² |

| Conductor cross section flexible, with ferrule without plastic sleeve max. | 2.5 mm² |

| Conductor cross section flexible, with ferrule with plastic sleeve min. | 0.25 mm² |

| Conductor cross section flexible, with ferrule with plastic sleeve max. | 1.5 mm² |

| 2 conductors with same cross section, solid min. | 0.2 mm² |

| 2 conductors with same cross section, solid max. | 1 mm² |

| 2 conductors with same cross section, stranded min. | 0.2 mm² |

| 2 conductors with same cross section, stranded max. | 1 mm² |

| 2 conductors with same cross section, stranded, TWIN ferrules with plastic sleeve, min. | 0.5 mm² |

| 2 conductors with same cross section, stranded, TWIN ferrules with plastic sleeve, max. | 1.5 mm² |

| 2 conductors with same cross section, stranded, ferrules without plastic sleeve, min. | 0.25 mm² |

| 2 conductors with same cross section, stranded, ferrules without plastic sleeve, max. | 1.5 mm² |

| Connection in acc. with standard | IEC/EN 60079-7 |

| Conductor cross section solid min. | 0.2 mm² |

| Conductor cross section solid max. | 4 mm² |

| Conductor cross section AWG min. | 24 |

| Conductor cross section AWG max. | 12 |

| Conductor cross section flexible min. | 0.2 mm² |

| Conductor cross section flexible max. | 2.5 mm² |

| Stripping length | 7 mm |

| Screw thread | M3 |

| Tightening torque, min | 0.6 Nm |

| Tightening torque max | 0.8 Nm |

| Connection in acc. with standard | CSA |

| IEC 60947-7-2 | |

| Flammability rating according to UL 94 | V0 |

| Fire protection for rail vehicles (DIN EN 45545-2) R22 | HL 1 - HL 3 HL 1 - HL 3 HL 1 - HL 3 HL 1 - HL 3 |

| Fire protection for rail vehicles (DIN EN 45545-2) R23 | HL 1 - HL 3 HL 1 - HL 3 HL 1 - HL 3 HL 1 - HL 3 |

| Fire protection for rail vehicles (DIN EN 45545-2) R24 | HL 1 - HL 3 HL 1 - HL 3 HL 1 - HL 3 HL 1 - HL 3 |

| Fire protection for rail vehicles (DIN EN 45545-2) R26 | HL 1 - HL 3 HL 1 - HL 3 HL 1 - HL 3 HL 1 - HL 3 |

| REACh SVHC | 4-Nonylphenol, ethoxylated |

| Lead 7439-92-1 | |

| China RoHS | Environmentally Friendly Use Period = 50 |

| For details about hazardous substances go to tab “Downloads”, Category “Manufacturer's declaration” |

| eCl@ss 4.0 | 27141118 |

| eCl@ss 4.1 | 27141118 |

| eCl@ss 5.0 | 27141118 |

| eCl@ss 5.1 | 27141100 |

| eCl@ss 6.0 | 27141100 |

| eCl@ss 7.0 | 27141141 |

| eCl@ss 8.0 | 27141141 |

| eCl@ss 9.0 | 27141141 |

| ETIM 2.0 | EC000901 |

| ETIM 3.0 | EC000901 |

| ETIM 4.0 | EC000901 |

| ETIM 5.0 | EC000901 |

| ETIM 6.0 | EC000901 |

| UNSPSC 6.01 | 30211811 |

| UNSPSC 7.0901 | 39121410 |

| UNSPSC 11 | 39121410 |

| UNSPSC 12.01 | 39121410 |

| UNSPSC 13.2 | 39121410 |

Cầu nối điện 2-tầng 2.5mm2 500V 22A Push-in Phoenix Contact PTTBS 2,5 - 3209604Giá tốt nhất xem...0909186879 Email

Cầu nối điện 2-tầng 2.5mm2 500V 22A Push-in Phoenix Contact PTTBS 2,5 - 3209604Giá tốt nhất xem...0909186879 Email Cầu nối điện-tín hiệu cầu chì Phoenix Contact UK 5-HESI - 3004100Giá tốt nhất xem...0909186879 Email

Cầu nối điện-tín hiệu cầu chì Phoenix Contact UK 5-HESI - 3004100Giá tốt nhất xem...0909186879 Email Cầu nối điện-tín hiệu Knife-disconnect Phoenix Contact UK 5-MTK - 3004430Giá tốt nhất xem...0909186879 Email

Cầu nối điện-tín hiệu Knife-disconnect Phoenix Contact UK 5-MTK - 3004430Giá tốt nhất xem...0909186879 Email Cầu nối tín hiệu-điện Phoenix Contact UK 3 N - 3001501 | 2.5mm2 800V 24AGiá tốt nhất xem...0909186879 Email

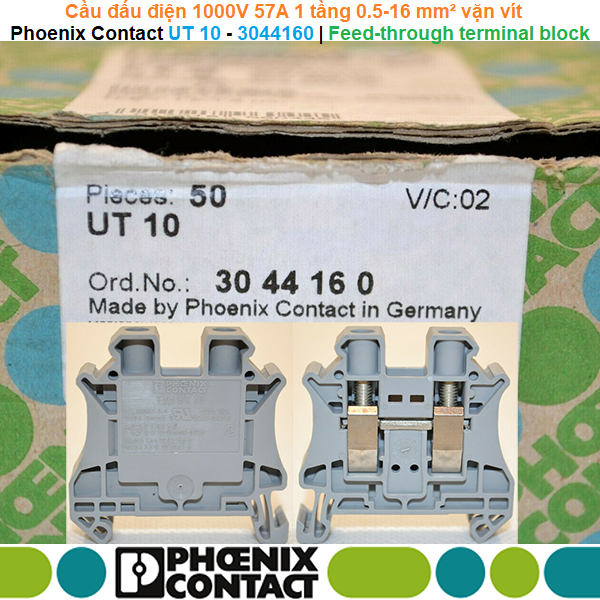

Cầu nối tín hiệu-điện Phoenix Contact UK 3 N - 3001501 | 2.5mm2 800V 24AGiá tốt nhất xem...0909186879 Email Phoenix Contact UT 10 - 3044160 | Cầu đấu điện Feed-through terminal blockGiá tốt nhất xem...0909186879 Email

Phoenix Contact UT 10 - 3044160 | Cầu đấu điện Feed-through terminal blockGiá tốt nhất xem...0909186879 Email Cầu nối tín hiệu-điện Phoenix Contact UK 3 N - 3001501 | 2.5mm2 800V 24A Feed-through Screw GrayGiá tốt nhất Xem...0909186879 Email

Cầu nối tín hiệu-điện Phoenix Contact UK 3 N - 3001501 | 2.5mm2 800V 24A Feed-through Screw GrayGiá tốt nhất Xem...0909186879 Email Cầu đấu nối điện Phoenix Contact PT 2,5 - 3209510 | 2.5mm2 800V 24A Feed-through Push-in GrayGiá tốt nhất Xem...0909186879 Email

Cầu đấu nối điện Phoenix Contact PT 2,5 - 3209510 | 2.5mm2 800V 24A Feed-through Push-in GrayGiá tốt nhất Xem...0909186879 Email Cầu đấu nối điện Phoenix Contact UT 2,5 - 3044076 | 1000V 24A 2.5mm2 Screw GrayGiá tốt nhất Xem...0909186879 Email

Cầu đấu nối điện Phoenix Contact UT 2,5 - 3044076 | 1000V 24A 2.5mm2 Screw GrayGiá tốt nhất Xem...0909186879 Email Cầu đấu nối điện Phoenix Contact UK 10 N - 3005073 | 10mm2 800V 57A Screw GrayGiá tốt nhất Xem...0909186879 Email

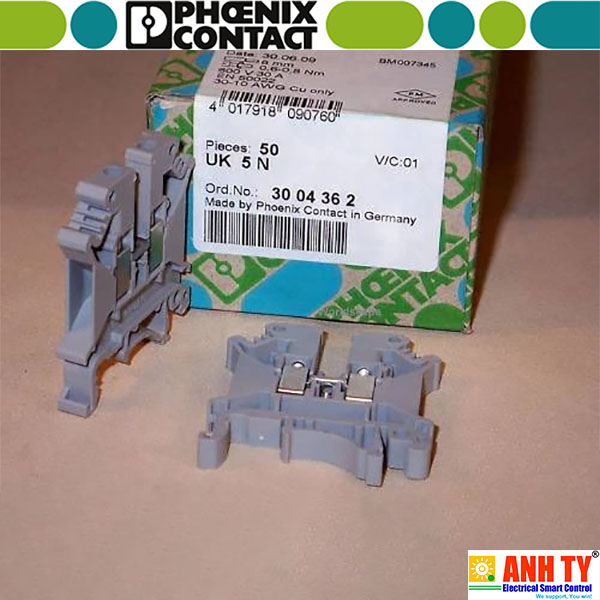

Cầu đấu nối điện Phoenix Contact UK 10 N - 3005073 | 10mm2 800V 57A Screw GrayGiá tốt nhất Xem...0909186879 Email Cầu đấu nối điện Phoenix Contact UK 5 N - 3004362 | 5mm2 800V 32A Feed-through Screw GrayGiá tốt nhất Xem...0909186879 Email

Cầu đấu nối điện Phoenix Contact UK 5 N - 3004362 | 5mm2 800V 32A Feed-through Screw GrayGiá tốt nhất Xem...0909186879 Email Cầu đấu điện có cầu chì Phoenix Contact UT 4-HESI (5X20) - 3046032 | 4mm2 500V 6.3A G/5x20 Screw ĐenGiá tốt nhất Xem...0909186879 Email

Cầu đấu điện có cầu chì Phoenix Contact UT 4-HESI (5X20) - 3046032 | 4mm2 500V 6.3A G/5x20 Screw ĐenGiá tốt nhất Xem...0909186879 Email Cầu đấu nối điện Phoenix Contact UK 16 N - 3006043 | 16mm2 800V 76A Feed-through ScrewGiá tốt nhất Xem...0909186879 Email

Cầu đấu nối điện Phoenix Contact UK 16 N - 3006043 | 16mm2 800V 76A Feed-through ScrewGiá tốt nhất Xem...0909186879 Email Cầu đấu nối điện Phoenix Contact UIK 35 - 3006182 | 35mm2 800V 125A ScrewGiá tốt nhất Xem...0909186879 Email

Cầu đấu nối điện Phoenix Contact UIK 35 - 3006182 | 35mm2 800V 125A ScrewGiá tốt nhất Xem...0909186879 Email Cầu đấu nối điện Phoenix Contact TB 6 I - 3000486 | 800V 41A 6mm2 Feed-through Screw XámGiá tốt nhất Xem...0909186879 Email

Cầu đấu nối điện Phoenix Contact TB 6 I - 3000486 | 800V 41A 6mm2 Feed-through Screw XámGiá tốt nhất Xem...0909186879 Email