Thông tin chi tiết sản phẩm

Cảm biến áp suất Pressure sensor 100kPa PNP R1/8 4-20mA 12-24vDC - Autonics - PSAN PSAN-LC01CPA-R1/8

Thông số kỹ thuật

| Chất lỏng áp dụng |

(Loại chất lỏng) Khí, khí không ăn mòn và chất lỏng không ăn mòn thép không rỉ 316L |

| Hướng lắp đặt cổng áp suất |

Đáy lắp |

| Cổng áp suất |

R1/8 |

| Loại kết nối |

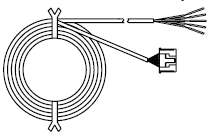

Loại giắc cắm(Loại giắc cắm cáp: 2m) |

| Loại áp suất |

Áp suất nén |

| Dải áp suất định mức |

-101,3 đến 100,0kPa |

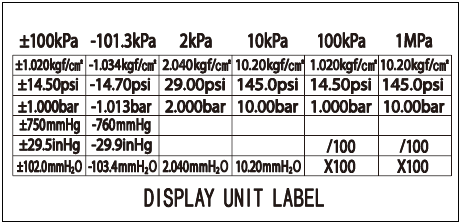

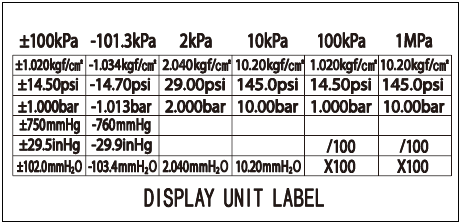

| Đơn vị áp suất hiển thị |

kPa, kgf/cm², bar, psi, mmHg, inHg, mmH₂O |

| Ngõ ra điều khiển_PNP mạch thu hở |

PNP mạch thu hở |

| Ngõ ra/ngõ vào tùy chọn |

Ngõ ra dòng (DC4-20mA) |

| Nguồn cấp |

12-24VDC  ±10%(sóng P-P: max. 10%) ±10%(sóng P-P: max. 10%) |

| Dòng tiêu thụ |

Loại ngõ ra điện áp: Max. 50mA

Loại ngõ ra dòng: Max. 75mA |

| Cấu trúc bảo vệ |

IP40 |

| Tiêu chuẩn |

|

| Ngõ ra điều khiển_Độ trễ |

Min. hiển thị interval |

| Ngõ ra điều khiển_Lỗi lặp lại |

± 0.2% F.S. ± khoảng hiển thị tối thiểu |

| Ngõ ra điều khiển_Thời gian đáp ứng |

Tùy chọn 2.5ms, 5ms, 100ms, 500ms, 1000ms |

| Môi trường_Nhiệt độ xung quanh |

-10 đến 50℃, bảo quản: -20 đến 60℃ |

| Môi trường_Độ ẩm xung quanh |

30 đến 80% RH, bảo quản: 30 đến 80% RH |

| Chất liệu |

Vỏ mặt trước: Polycarbonate, Vỏ bánh răng: Polyamide 6, Cổng áp suất: Stainless steel 316L |

| Trọng lượng |

Xấp xỉ 173g(Xấp xỉ 88g) |

- Đối với chế độ ngõ ra độ trễ, sự khác biệt phát hiện là biến số.

- Chỉ được phép chọn một loại ngõ ra analog.

- Trọng lượng bao gồm bao bì. Trọng lượng trong ngoặc là trọng lượng thiết bị.

- F.S : Áp suất định mức.

- Có thể lỗi ± 1 chữ số do lỗi tính toán đơn vị áp suất.

- Nhiệt độ hoặc độ ẩm được đề cập trong mục Môi trường được đo ở điều kiện không đông đặc hoặc ngưng tụ.

| Control |

Standard (fluid) |

| Pressure range |

100 kpa |

| Control output |

PNP |

| Cable Type |

Analog current |

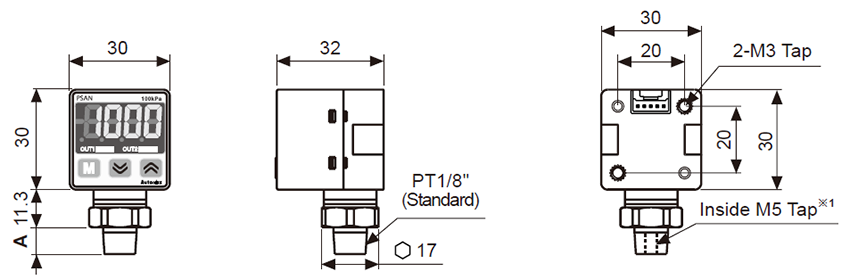

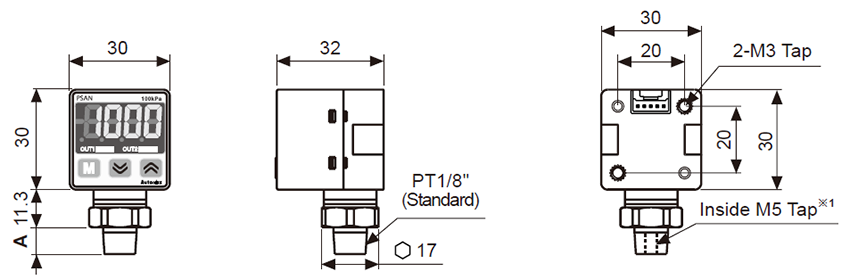

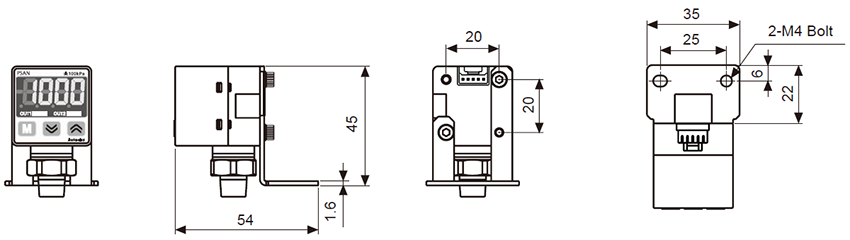

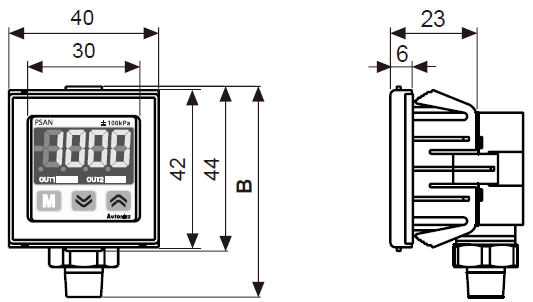

Kích thước

※(A) PT1/8" model(Standard): 8, NPT1/8" model: 8, 7/16"-20 UNF model: 11

※1: Only for PT1/8" model, NPT1/8" model

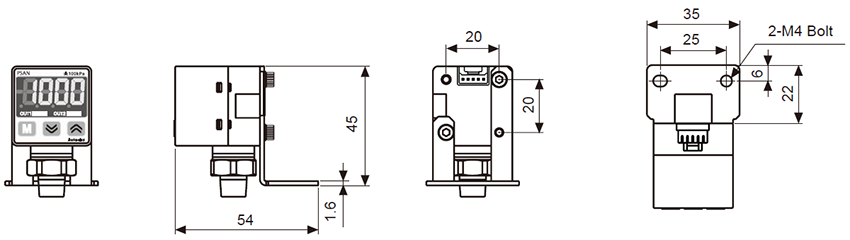

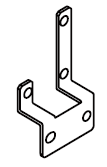

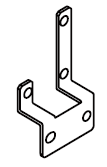

Fixing bracket A for mounting

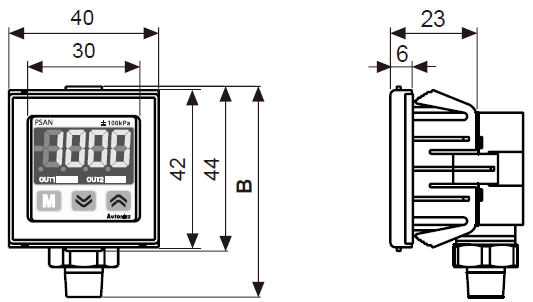

When front cover is mounted

When front cover is mounted

※(B) PT1/8" model(Standard): 56.3, NPT1/8" model: 56.3, 7/16"-20 UNF model: 59.3

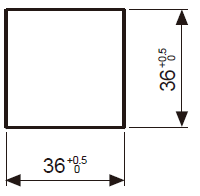

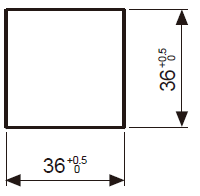

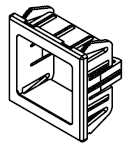

Panel cut-out

(Panel thickness: 0.8mm to 3.5mm)

Accessory

Pressure unit label

Bracket A

Bracket A

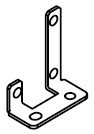

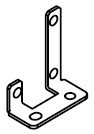

Bracket B

Bracket B

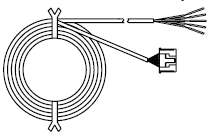

Connector cable (PSO-C01, 2m)

Connector cable (PSO-C01, 2m)

Sold separately

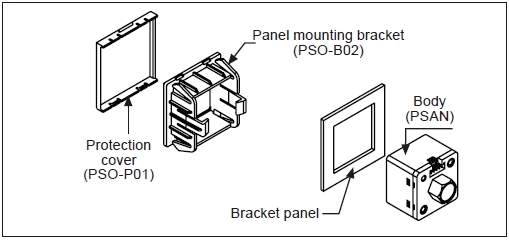

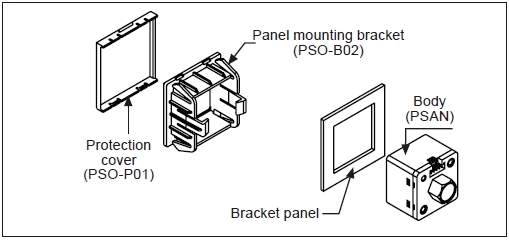

Panel mounting bracket (PSO-P01)

Front protection cover (PSO-B02)

M5 Gender (PSO-Z01)

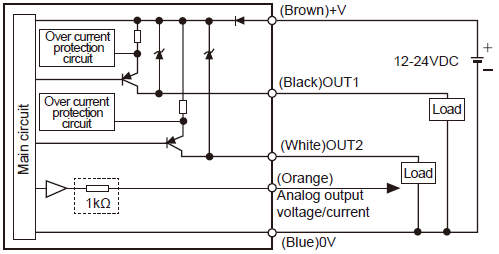

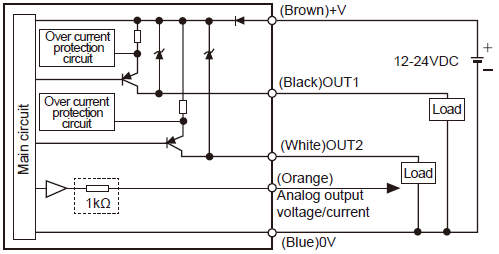

Sơ đồ điều khiển

Voltage (1-5VDC) output type (PSAN- .png)

.png)

.png)

.png)

.png) V-

V- .png) )

)

Current(DC4-20mA) output type (PSAN- .png)

.png)

.png)

.png)

.png) A-

A- .png) )

)

PNP open collector output type

※In case of analog voltage output type models short-circuit protection is not embodied. ( : For voltage output type only.) Do not connect with power source or load directly.

※Be careful with input impedance of connecting devices when using analog voltage output type models.

※Be careful with voltage drop due to cable resistance when extending sensor cable.

Hold/Auto shift input (PSAN- .png)

.png)

.png)

.png)

.png) H-

H- .png) )

)

PNP open collector output type

.png)

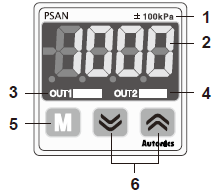

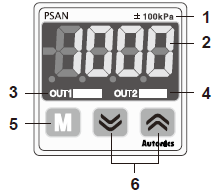

Front panel identification and function

1.

Range of rated pressure: It is possible to change the pressure unit in Pressure sensor.

Use different unit as label for your application.

2.

4digit LED display(Red): Used to indicate measured pressure value, setting value and error message.

3.

Output1 indicator(Red): Output 1 is

ON,

LED will be

ON.

4.

Output2 indicator(Green): Output 2 is

ON,

LED will be

ON.

5.

key

key: Used to enter into Preset/Parameter setting mode and to save Setting mode.

6.

,

key

key: Used to set parameter and preset, peak value check mode, function setting or output operation mode.

+

key : Used for zero point adjustment function by pressing + keys over 1 sec simultaneously in RUN mode.

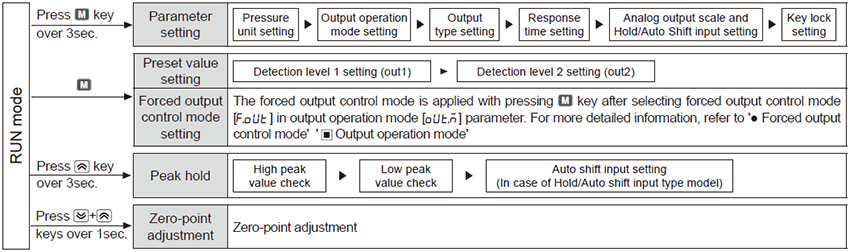

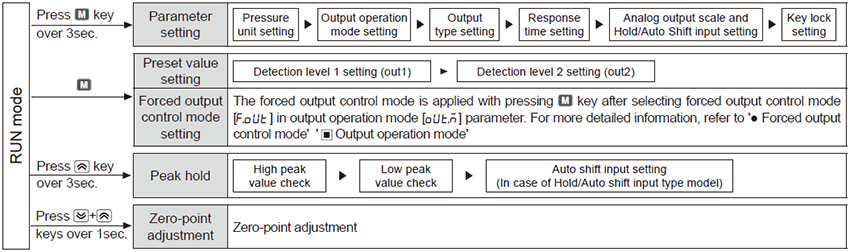

Cài đặt Settings

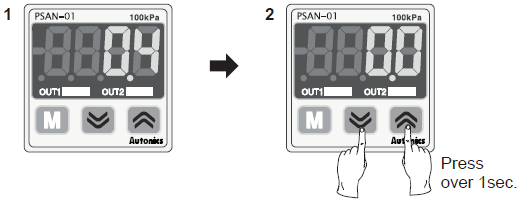

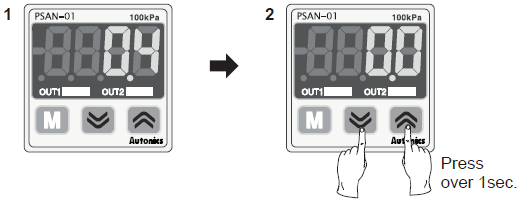

Điều chỉnh Zero point adjustment

1. In state of atmospheric pressure during RUN mode, press key and key at the same time for over 1sec.

2. When the zero-point adjustment is completed, it will display )0 and return to RUN mode automatically.

※Please execute zero-point adjustment regularly.

If executing zero point adjustment when external pressure has been applied

, ERR1 will flash.

Please execute zero-point adjustment again in state of atmospheric pressure without external pressure.

Cài đặt tham số

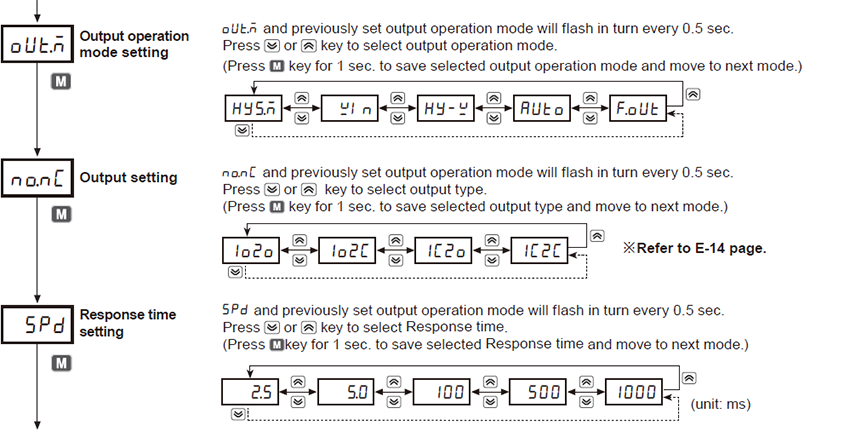

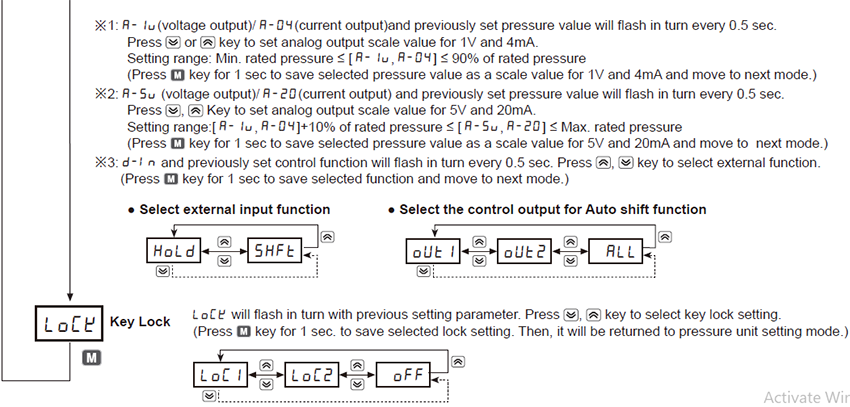

1. It is able to set pressure unit, display resolution, output operation mode, output type, Response time, analog output scale, Hold/Auto shift and key lock setting in parameter setting mode.

2. If the key lock is set (lock1 or lock2), unlock the key lock before setting parameters. (Refer to Key Lock setting below.)

※When pressing key for 3 sec. in the middle of parameter setting, current setting value will be saved in EEPROM and it will be returned to RUN mode.

※ All settings are saved in EEPROM regardless of power failure. Make sure that EEPROM has a limited write life cycle(100,000 times).

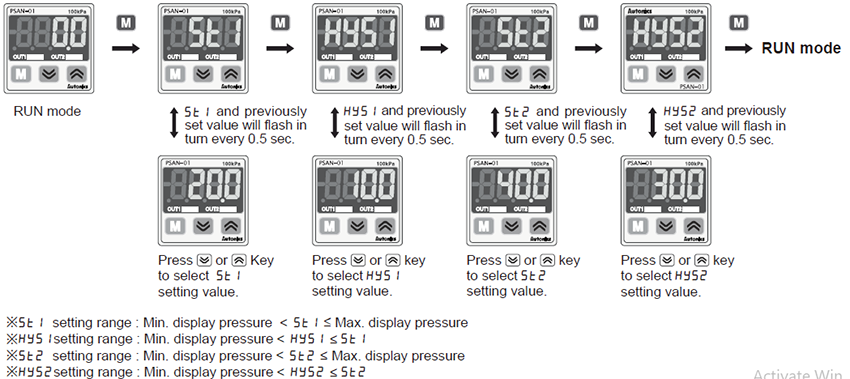

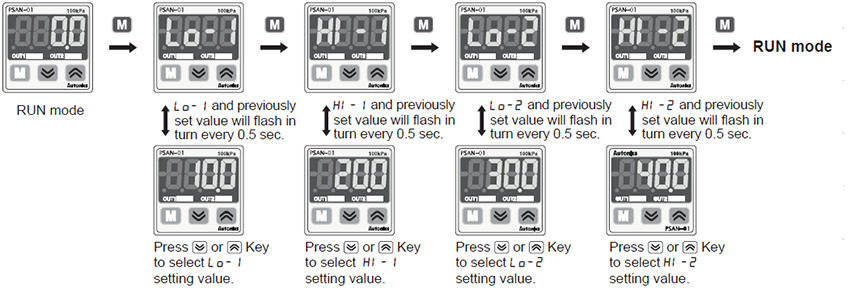

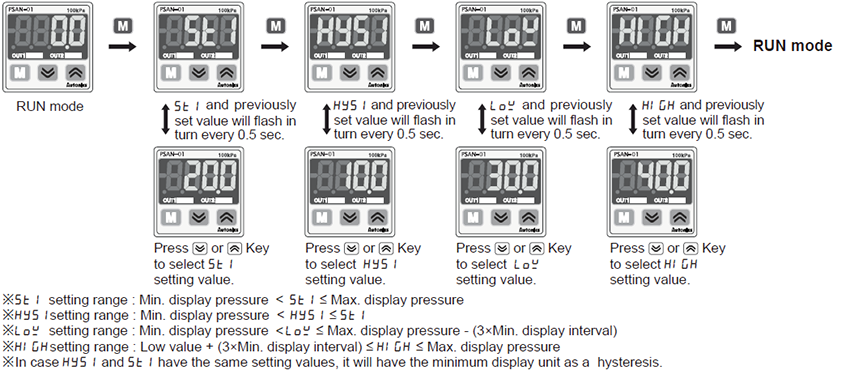

Thiết lập cài đặt lại Preset setting

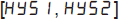

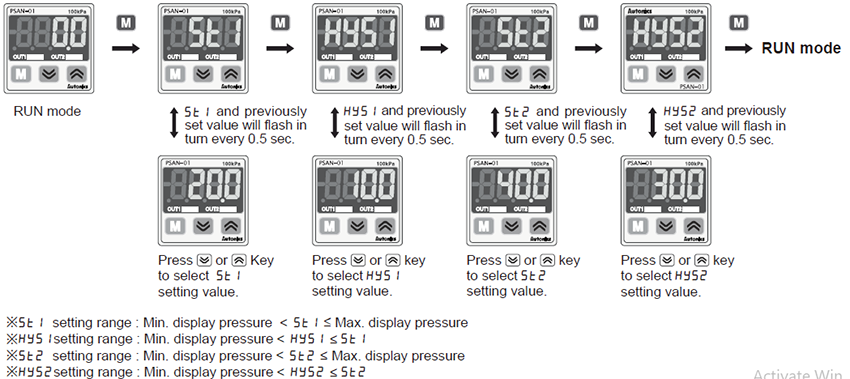

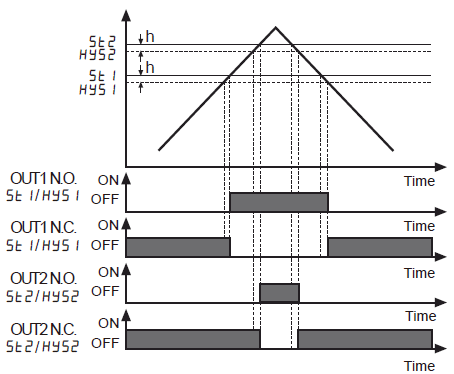

Hysteresis mode

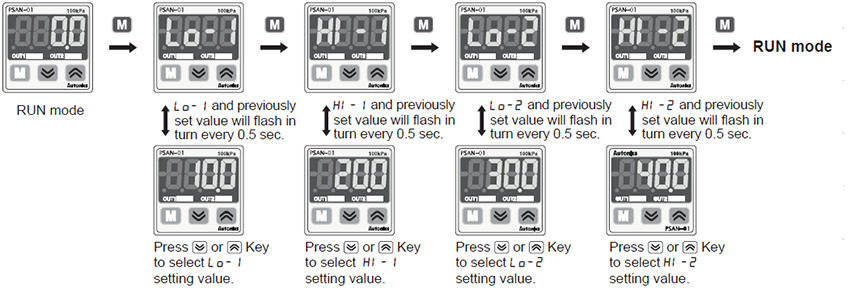

Window comparison output mode

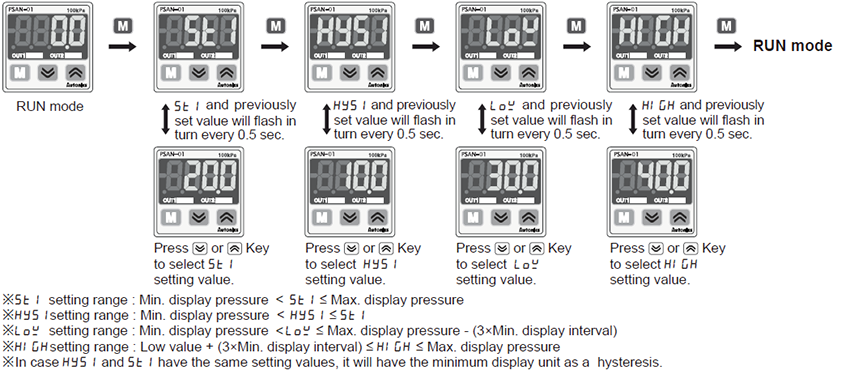

Hysteresis-Window comparison output mode

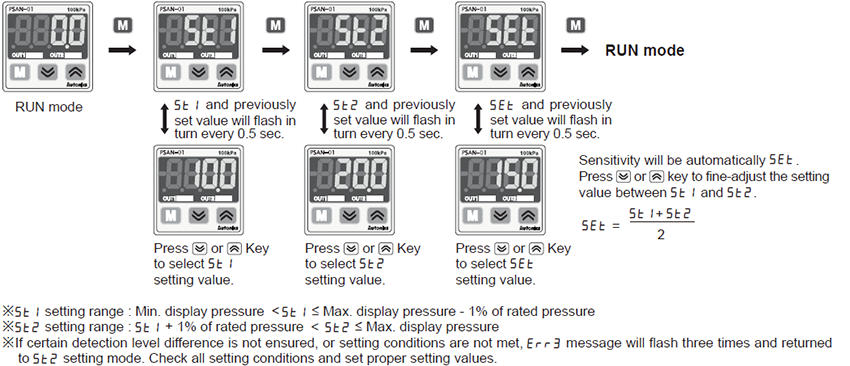

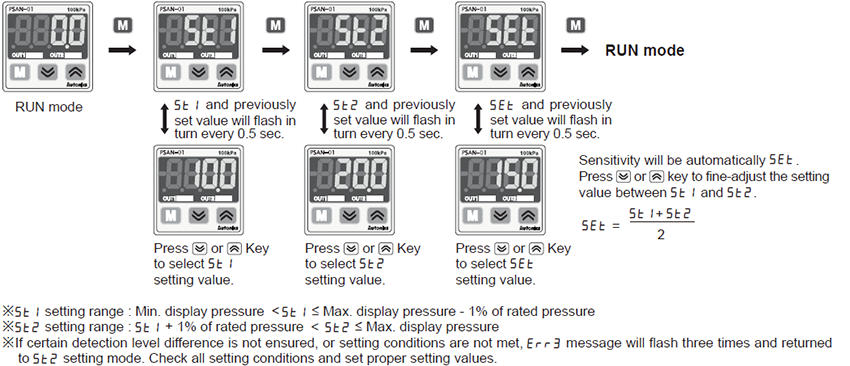

Automatic sensitivity setting mode

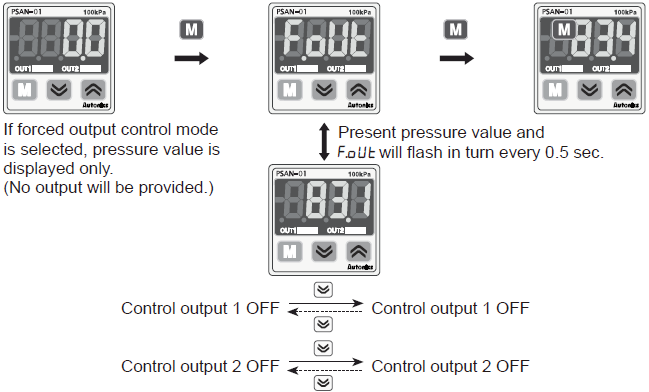

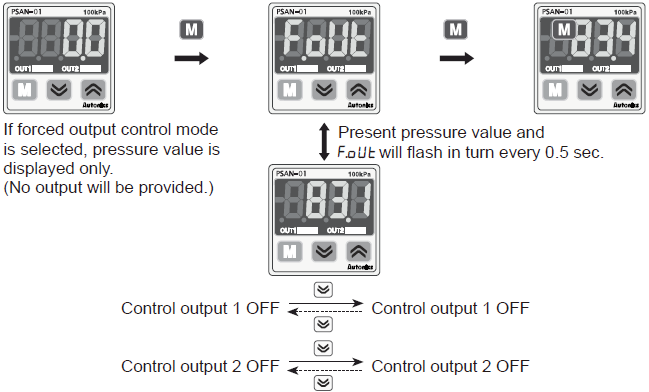

Forced output control mode

※If there is no additional key operation within 60 sec while setting, it is returned to Run mode (Except for force output mode). Previously set values are remained.

※In case of changing output operation mode, no preset values will be initialized. Instead, previous output operation settings will become the preset values.

※When using the forced output function, Hold/Auto shift function is not available to use in Hold/Auto shift model.

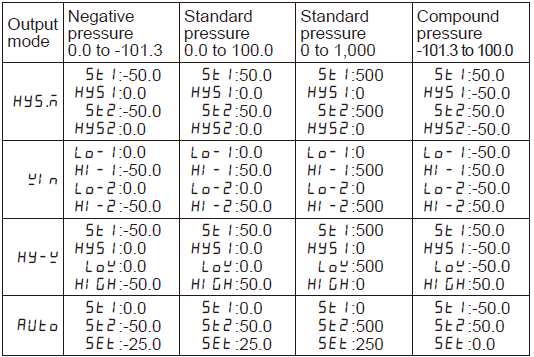

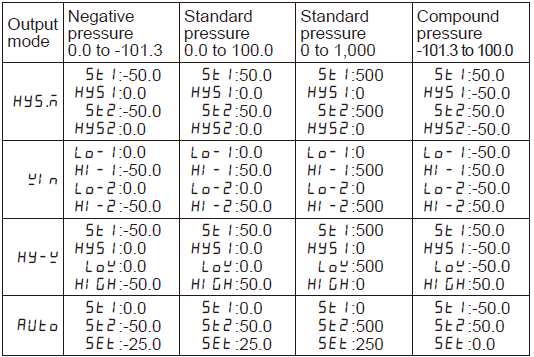

※When changing pressure display unit, resolution, and Hold Auto shift input function, preset values will be initialized as shown the next table. (When changing pressure display unit, preset value will be automatically switched to changed pressure unit.)

Factory default (unit: kPa)

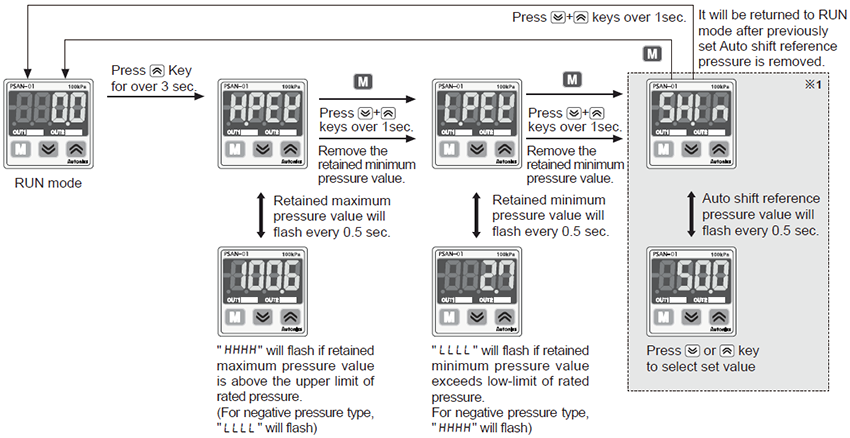

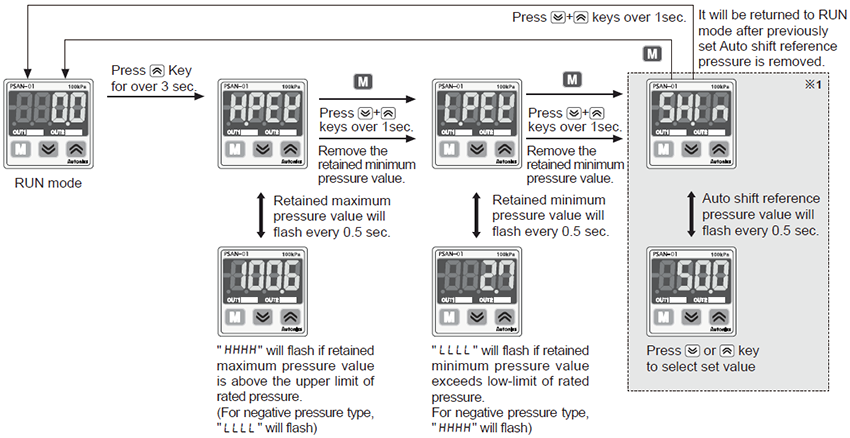

High peak/Low peak function and Auto shift reference pressure check/change

※1: Displayed only when D-IN is set to SHFT(PSAN-

.png)

.png)

.png)

.png)

.png)

H-

.png)

models only)

※If there is no Auto shift input, "0" will be displayed.(Refer to E-14 page for more details.)

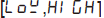

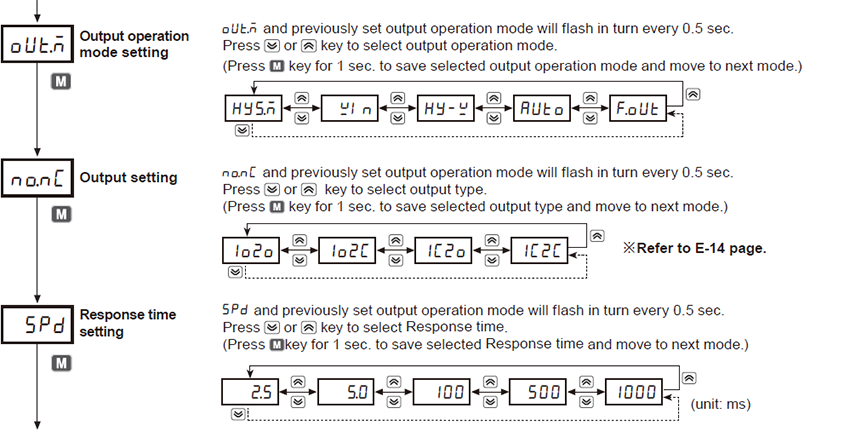

Output operation mode

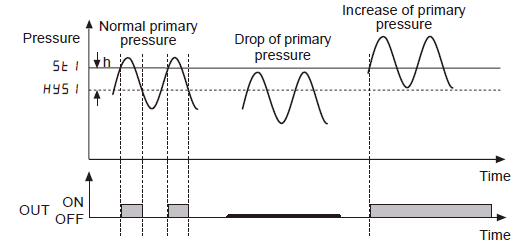

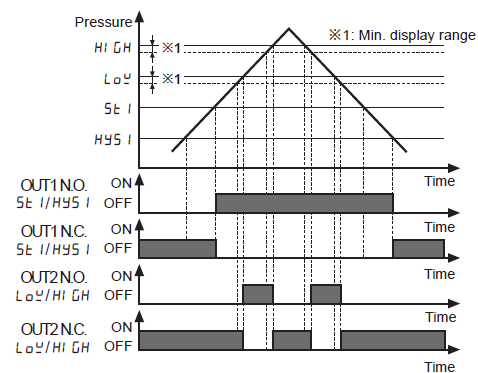

1. Hysteresis mode

It is able to set certain value for pressure detection level

and hysteresis

.

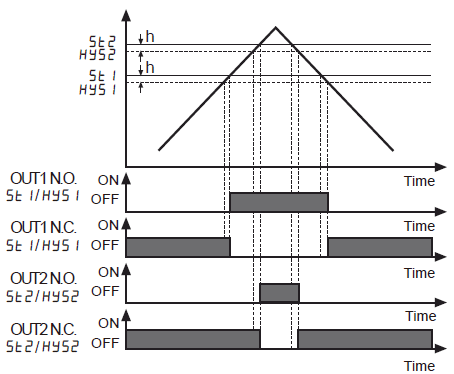

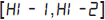

2. Window comparison output mode

① It is able to set the range for high

, low

limit of pressure detection level when it is required to detect pressure at a certain range.

② Detection hysteresis is fixed to min. display range.

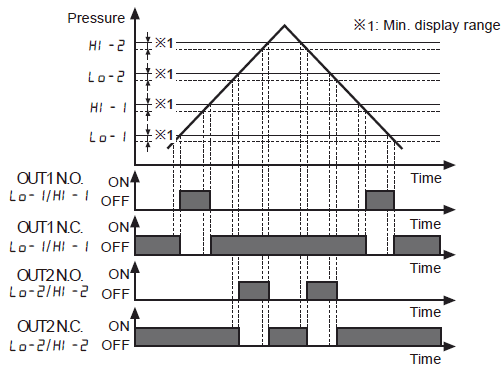

3. Hysteresis-window comparison output mode

① It is available to set hysteresis mode and window comparison output mode when both hysteresis mode

and window comparison output mode

are necessary.

② Detection hysteresis is fixed to min. display range.

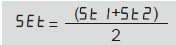

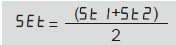

4. Automatic sensitivity setting mode

① This function is to set pressure detection level to the proper position automatically. It is set by applied pressure from two positions

.

② Detection hysteresis is fixed to min. display range.

③ The pressure detection level

is shown in the following calculation.

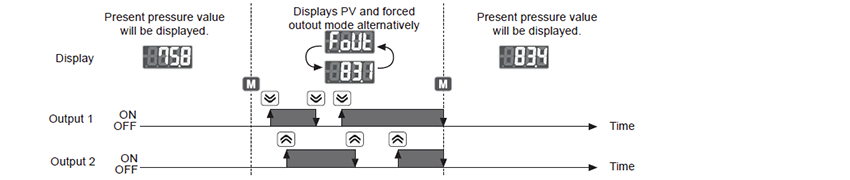

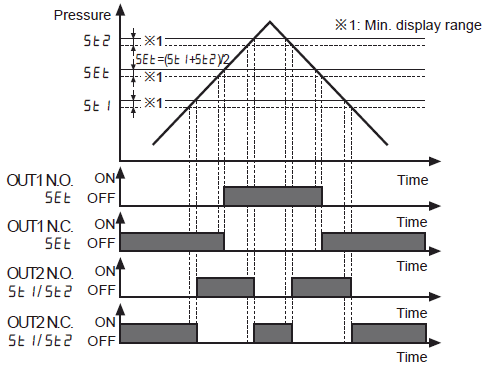

5. Forced output control mode

① Used to display pressure with forcibly holding comparing output

OFF regardless of setting value.

② In parameter setting, if output operation mode setting

is changed to

, forced output control mode is operated.

③ Output 1, 2 can be ON/OFF manually by pressing , key while the forced output control mode is applied.

Chức năng

Pressure unit change

PSAN-V01C(P) and PSAN-C01C(P) has 7 kinds of pressure unit, PSAN-01C(P) and PSAN-1C(P) has 5 kinds of pressure unit. Please select the proper unit for application.

• PSAN-V01C(P), PSAN-C01C(P): kPa, kgf/cm², bar, psi, mmHg, inHg, mmH2O

• PSAN-01C(P), PSAN-1C(P) : MPa, kPa, kgf/cm², bar, psi

※When using mmH2O unit, multiply display value by 100.

Output mode change

There are 5 kinds of control output mode in order to realize the various pressure detection.

• Hysteresis mode [HYsM] When needed to change hysteresis for detecting pressure.

• Window comparison output mode [WIN] When needed to detect pressure in certain area.

• Hysteresis - Window comparison output mode [HY-W] When both hysteresis mode and window comparison output mode are required.

• Automatic sensitivity setting mode [ AUTO] When needed to set detection sensitivity automatically at proper position.

• Forced output control mode [ fOUT] When needed to display pressure with remaining comparison output OFF regardless of setting value.

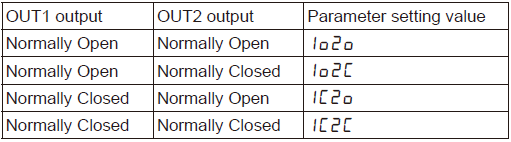

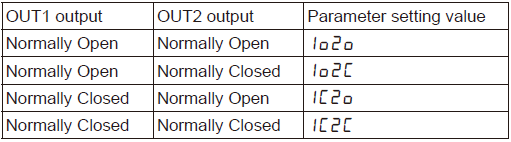

Control output change

Type of control output for Out1 and Out2 can be able to set Normally Open or Normally Closed.

※Note that Normally Open and Normally Closed provide opposite output.

Response time change (chattering prevention)

It can prevent chattering of control output by changing Response time. It is able to set 5 kinds of Response time (2.5ms, 5ms, 100ms, 500ms, 1000ms) and if the Response time is getting longer, the detection will be more stable by increasing the number.

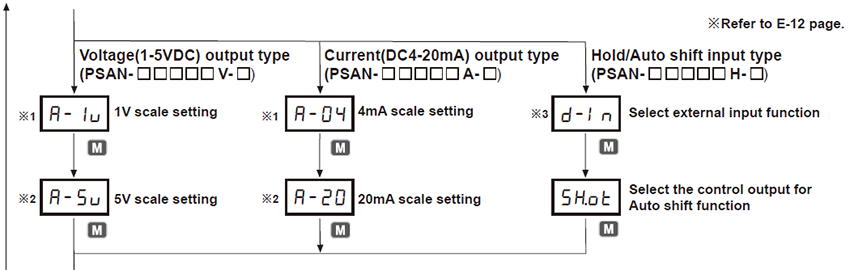

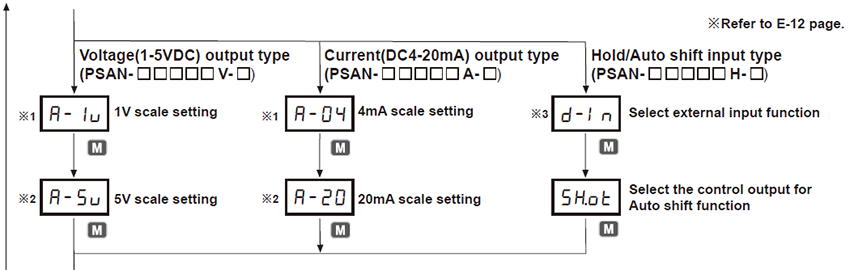

Analog output scale setting

Analog voltage output scale setting

The scale function for analog output voltage(1-5VDC) is not fixed to the rated pressure range. It can be changed for User's application. Analog output voltage range will be fixed to 1-5VDC within the pressure range from pressure point of 1VDC output [A-1V] to pressure point of 5VDC output [A-SV].

• Analog current output scale setting

The scale for analog output Current (DC4-20mA) is not fixed to the rated pressure range. It can be changed for User's application. Analog output voltage will be fixed to 4-20mA within the rated pressure range from pressure point of 4mA output [A-04] to pressure point of 20mA output [A-20].

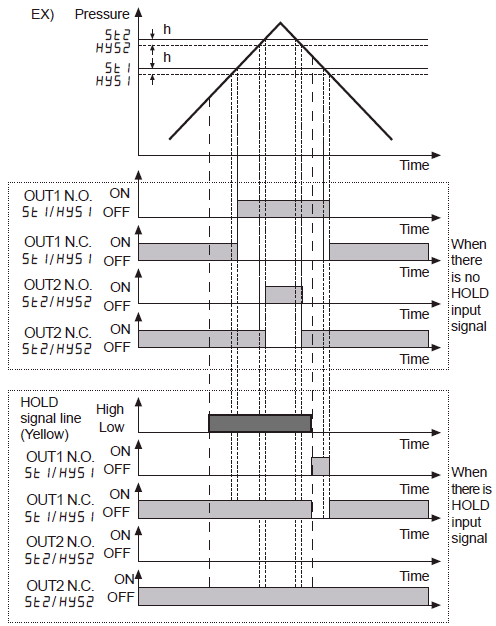

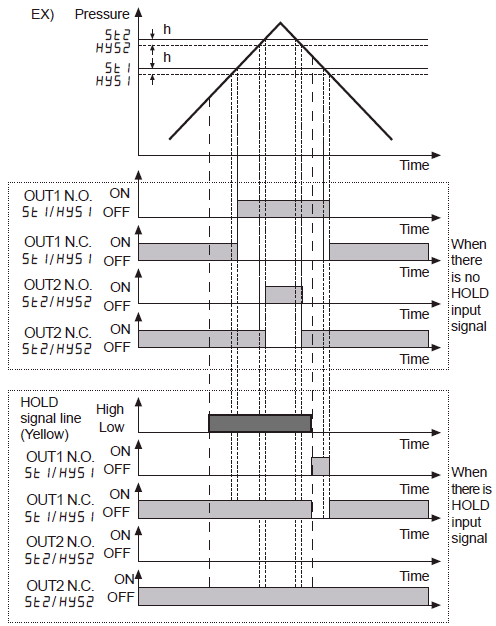

Hold/Auto shift input setting

• Hold

A function to hold present pressure value and control output at the time of hold signal input.

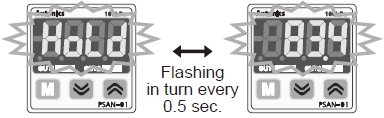

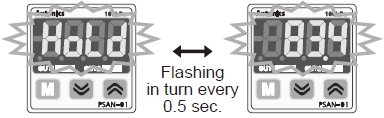

※Present pressure value and Hold message will flash in turn every 0.5 sec. while Hold function is set. Make sure that Hold function is not able to execute while forced output mode is executed.

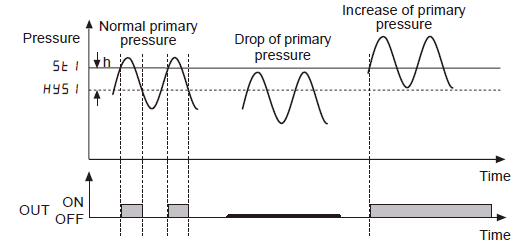

▶ Control output timing chart

When Hold signal is applied in Hysteresis mode, refer to ' Control output diagram'

※[ HOLD] and present pressure value will flash in turn every 0.5 sec. while Hold signal is applied.

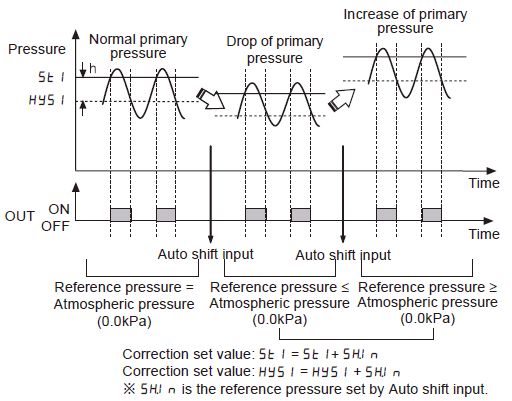

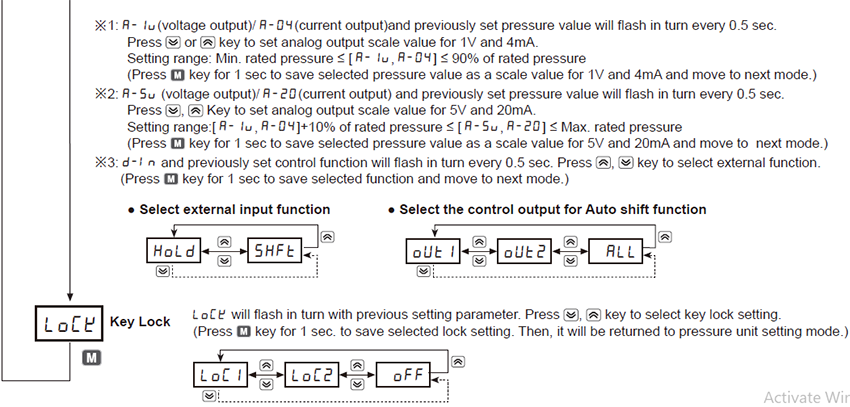

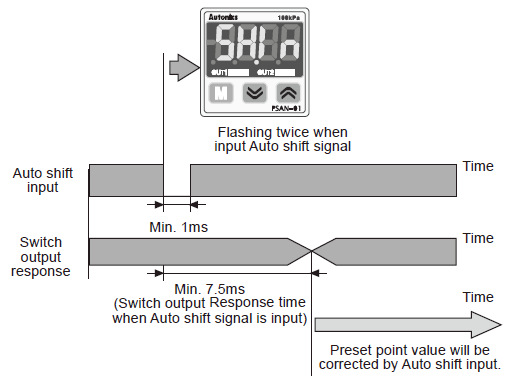

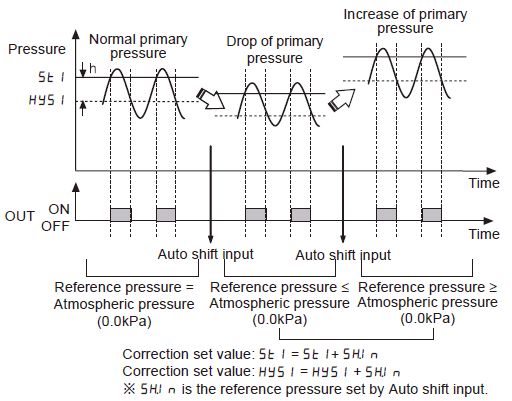

• Auto shift

• Auto shift

A function to use the measured pressure at the moment of auto shift input as a reference pressure in order to correct the set point values of control output when initial pressure changes.

※Reference pressure is fixed to atmospheric pressure (0.0kPa) when Auto shift function is not used.

※ShIN(Auto shift compensation value) will be reset to 0 when changing control output or preset values.

※Auto shift function will not be executed if " HHHH" or " LLLL" error occurs or if forced output mode is set.

• ShOT: Reference pressure change through setting.

• OUT1: Changed reference will be applied to control output 1 only.

• OUT2: Changed reference will be applied to control output 2 only.

• ALL: Changed reference will be applied to both control output 1 and control output 2.

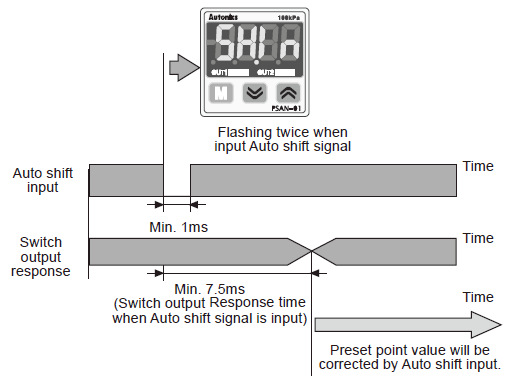

▶ When Auto shift is used

When Auto shift input signal remains at low level more than 1ms, the measured pressure at this point will be saved as a reference value to make correct judgment regardless of pressure changes. Corrected preset pressure value will be applied after 7.5ms. Measured reference pressure value will be saved in [ShIN].

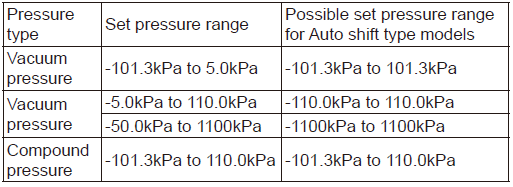

※When Auto shift function is used, the possible set pressure range will be wider than rated set pressure range.

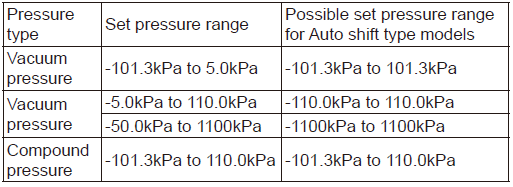

※The possible set pressure range for Auto shift type models.

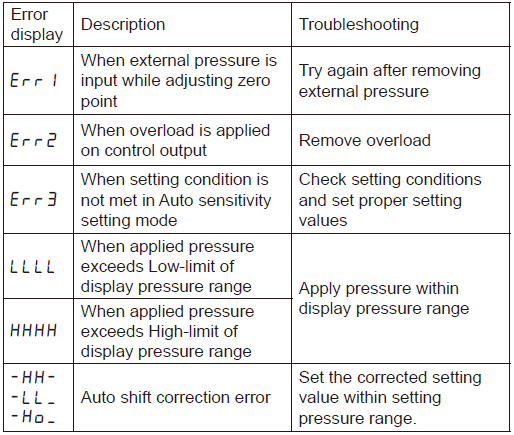

※ If the set point value corrected by auto shift input exceeds set pressure range,an error message will flash three times and corrected value is not saved.

→[-HH-] displayed when the set point value corrected by Auto shift input is above the upper limit of set pressure range.

→ [-LL-] displayed when the set point value corrected by Auto shift input is below the lower limit of set pressure range.

※The correction value will be saved in EEPROM.

▶ Example of Auto shift

< When Auto shift is not used >

< When Auto shift is used >

Key lock

Key lock

The key lock function prevents key operations so that conditions set in each mode.

• LOC1: All keys are locked; therefore it is not available to change parameter settings, preset value, zero adjustment, High/Low peak check, and ShIN data initialization. (Lock setting change is available)

• LOC2: Partially locked status; therefore it is not available to change parameter settings only(Lock setting change is available). Other settings are still available.

• OFF: All of the setting is available, all keys are unlocked. to set detection sensitivity automatically at proper position.

Zero-point adjustment

The key lock function prevents key operations so that conditions set in each mode.

The zero-point adjustment function forcibly sets the pressure value to "zero" when the pressure port is opened to atmospheric pressure. When the zero adjustment is applied, analog output [Voltage or Current] is changed by this function.

(Press

+

keys over 1 sec. in RUN mode.)

High Peak / Low Peak Hold

This function is to diagnosis malfunction of the system caused by parasitic pressure or to check through memorizing the max./min. pressure occurred from the system.

Hướng dẫn Cài đặt sử dụng đúng cách

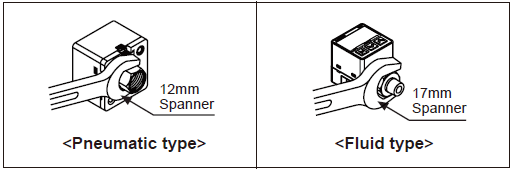

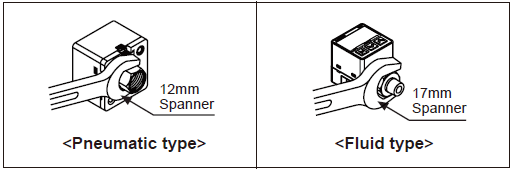

1. Pressure port is divided as basic and option specification.

Therefore, be sure that to use commercially available one touch fitting. (Standard: (pneumatic type): Rc1/8", (fluid type): R(PT)1/8", Option: NPT1/8", R1/8")

2. Please connect it by using spanner: (pneumatic type)

12mm, (fluid type) 17mm at the metal part in order not to overload on the body when connecting one touch fitting.

Caution

The tightening torque of one touch fitting should be max.100kgf.cm. If not, it may cause mechanical problem.

Caution

The tightening torque of one touch fitting should be max.100kgf.cm. If not, it may cause mechanical problem.

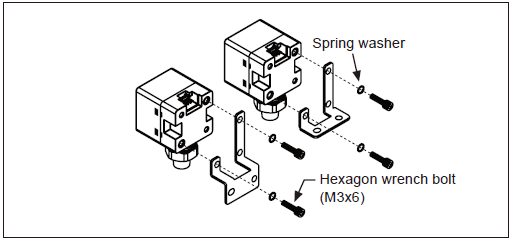

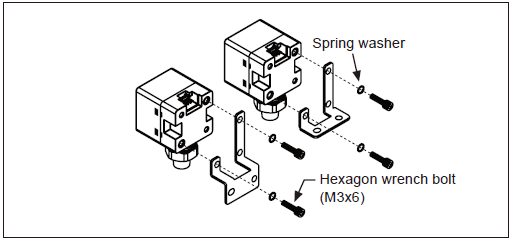

3. Two different fixing brackets are provided for PSAN model. Select proper one with considering your application environments.

4. At first, please unscrew hexagon wrench bolt and assemble the bracket on this unit by fixing hexagon the wrench bolt.

Caution

In this case, tightening torque of hexagon wrench should be max. 30kgf.cm. If not, it may cause mechanical problem.

Caution

In this case, tightening torque of hexagon wrench should be max. 30kgf.cm. If not, it may cause mechanical problem.

5. Bracket(PSO-B02) and front protection cover (PSOP01) are sold separately. Please see the pictures for installation.

Sử dụng hợp lý

Caution

PSAN Series is for sensing of non corrosive gas. Do not use this product at corrosive gas or flammable gas, etc.

• Please using this unit within the range of specification, if applying pressure is larger than specification, it may not be working properly due to damage.

• After supplying power, it takes 3 sec. to work.

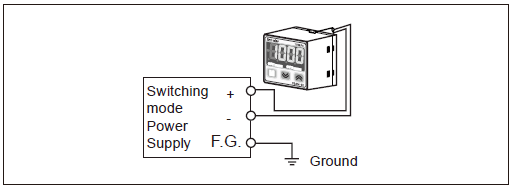

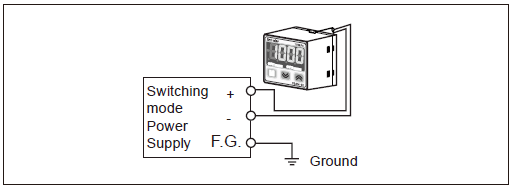

• When using switching mode power supply, frame ground (F.G.) terminal of power supply should be grounded.

• It may cause malfunction by noise, when wiring with power line or high voltage line.

• Do not insert any sharp or pointed object into pressure port. It may cause mechanical problem due to sensor damage.

• Do not use this unit with flammable gas, because this is not an explosion proof structure.

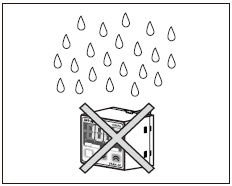

• Be sure that this unit should not be contacted directly with water, oil, thinner, etc.

• Wiring must be done with power off.

±10%(sóng P-P: max. 10%)

±10%(sóng P-P: max. 10%)

.png)

.png)

.png)

.png)

.png) V-

V- .png) )

).png)

.png)

.png)

.png)

.png) A-

A- .png) )

)

.png)

.png)

.png)

.png)

.png) H-

H- .png) )

).png)

key: Used to enter into Preset/Parameter setting mode and to save Setting mode.

key: Used to enter into Preset/Parameter setting mode and to save Setting mode. ,

,  key: Used to set parameter and preset, peak value check mode, function setting or output operation mode.

key: Used to set parameter and preset, peak value check mode, function setting or output operation mode. +

+  key : Used for zero point adjustment function by pressing + keys over 1 sec simultaneously in RUN mode.

key : Used for zero point adjustment function by pressing + keys over 1 sec simultaneously in RUN mode.

, ERR1 will flash.

, ERR1 will flash.

.png)

.png)

.png)

.png)

.png) H-

H- .png) models only)

models only)

and hysteresis

and hysteresis  .

.

, low

, low  limit of pressure detection level when it is required to detect pressure at a certain range.

limit of pressure detection level when it is required to detect pressure at a certain range.

and window comparison output mode

and window comparison output mode  are necessary.

are necessary.

.

. is shown in the following calculation.

is shown in the following calculation.

is changed to

is changed to  , forced output control mode is operated.

, forced output control mode is operated.

+

+  keys over 1 sec. in RUN mode.)

keys over 1 sec. in RUN mode.)

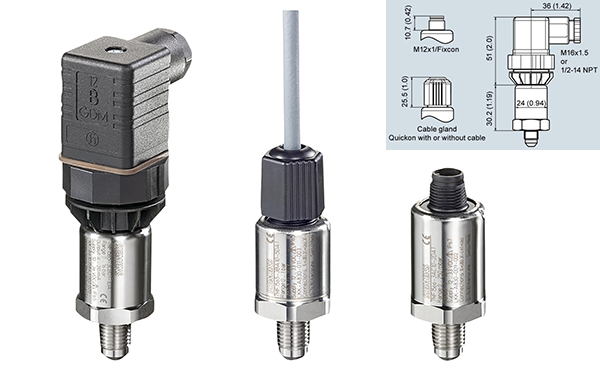

Cảm biến áp suất Telemecanique ACW1M119012 | 17-Bar 1CO Snap G1/4Giá tốt nhất xem...0909186879 Email

Cảm biến áp suất Telemecanique ACW1M119012 | 17-Bar 1CO Snap G1/4Giá tốt nhất xem...0909186879 Email Cảm biến áp suất đo mức thủy tĩnh Siemens 7MF1572-1CA10Giá tốt nhất xem...0909186879 Email

Cảm biến áp suất đo mức thủy tĩnh Siemens 7MF1572-1CA10Giá tốt nhất xem...0909186879 Email Cảm biến áp suất KITA - KP10B-R6Giá tốt nhất xem...0909186879 Email

Cảm biến áp suất KITA - KP10B-R6Giá tốt nhất xem...0909186879 Email Cảm biến chênh lệch áp suất không khí Siemens QBM3020-5D | Air ductGiá tốt nhất xem...0909186879 Email

Cảm biến chênh lệch áp suất không khí Siemens QBM3020-5D | Air ductGiá tốt nhất xem...0909186879 Email Cảm biến áp suất Siemens 7MF1567-3CA00-2CB1 | SITRANS P220 pressure transmittersGiá tốt nhất xem...0909186879 Email

Cảm biến áp suất Siemens 7MF1567-3CA00-2CB1 | SITRANS P220 pressure transmittersGiá tốt nhất xem...0909186879 Email![Màn hình kỹ thuật số hiển thị kép Cảm biến áp suất - Panasonic - 2 screen digital pressure sensor [for gas] DP-100 DP-102Z-M](https://dienelectric.com/images/product/Man-hinh-ky-thuat-so-hien-thi-kep-cho-Cam-bien-ap-suat-Panasonic-2-screen-digital-pressure-sensor-for-gas-DP-100 DP-102Z-M.png) Màn hình kỹ thuật số hiển thị kép Cảm biến áp suất - Panasonic - 2 screen digital pressure sensor [for gas] DP-100 DP-102Z-MGiá tốt nhất Xem...0909186879 Email

Màn hình kỹ thuật số hiển thị kép Cảm biến áp suất - Panasonic - 2 screen digital pressure sensor [for gas] DP-100 DP-102Z-MGiá tốt nhất Xem...0909186879 Email Cảm biến áp suất Pressure sensor 0-10 bar 4-20mA - Siemens - 7MF1565-3CA00-1AA1Giá tốt nhất Xem...0909186879 Email

Cảm biến áp suất Pressure sensor 0-10 bar 4-20mA - Siemens - 7MF1565-3CA00-1AA1Giá tốt nhất Xem...0909186879 Email Cảm biến áp suất Pressure sensor 100kPa PNP R1/8 4-20mA 12-24vDC - Autonics - PSAN PSAN-LC01CPA-R1/8Giá tốt nhất Xem...0909186879 Email

Cảm biến áp suất Pressure sensor 100kPa PNP R1/8 4-20mA 12-24vDC - Autonics - PSAN PSAN-LC01CPA-R1/8Giá tốt nhất Xem...0909186879 Email Siemens SITRANS P320 7MF0340-1MM01-5AF2-Z A00+E01+H01+Y01+Y21 - Cảm biến đo áp suất và mức chênh lệch 4-20mA/HART Silicone oil 1600 mbarGiá tốt nhất Xem...0909186879 Email

Siemens SITRANS P320 7MF0340-1MM01-5AF2-Z A00+E01+H01+Y01+Y21 - Cảm biến đo áp suất và mức chênh lệch 4-20mA/HART Silicone oil 1600 mbarGiá tốt nhất Xem...0909186879 Email Cảm biến áp suất Pressure sensor 0-16 bar 4-20mA - Siemens - 7MF1565-3CB00-1AA1Giá tốt nhất Xem...0909186879 Email

Cảm biến áp suất Pressure sensor 0-16 bar 4-20mA - Siemens - 7MF1565-3CB00-1AA1Giá tốt nhất Xem...0909186879 Email Cảm biến áp suất Schneider XMLA020A2S11 | 20-bar 1CO G1/4Giá tốt nhất Xem...0909186879 Email

Cảm biến áp suất Schneider XMLA020A2S11 | 20-bar 1CO G1/4Giá tốt nhất Xem...0909186879 Email Panasonic DP-101-E-P | Dual display digital pressure sensor -Đồng hồ kỹ thuật số hiển thị cảm biến áp suất -100..+100kPa 24VDC PNP NO/ NCGiá tốt nhất Xem...0909186879 Email

Panasonic DP-101-E-P | Dual display digital pressure sensor -Đồng hồ kỹ thuật số hiển thị cảm biến áp suất -100..+100kPa 24VDC PNP NO/ NCGiá tốt nhất Xem...0909186879 Email Siemens SITRANS P320 7MF0340-1GM01-5AF2-Z A00+E01+H01+Y01+Y21 - Cảm biến đo áp suất và mức chênh lệch 4-20mA/HART Silicone oil 250 mbarGiá tốt nhất Xem...0909186879 Email

Siemens SITRANS P320 7MF0340-1GM01-5AF2-Z A00+E01+H01+Y01+Y21 - Cảm biến đo áp suất và mức chênh lệch 4-20mA/HART Silicone oil 250 mbarGiá tốt nhất Xem...0909186879 Email Cảm biến áp suất Pressure sensor 0-6 bar 4-20mA - Siemens - 7MF1565-3BG00-1AA1Giá tốt nhất Xem...0909186879 Email

Cảm biến áp suất Pressure sensor 0-6 bar 4-20mA - Siemens - 7MF1565-3BG00-1AA1Giá tốt nhất Xem...0909186879 Email